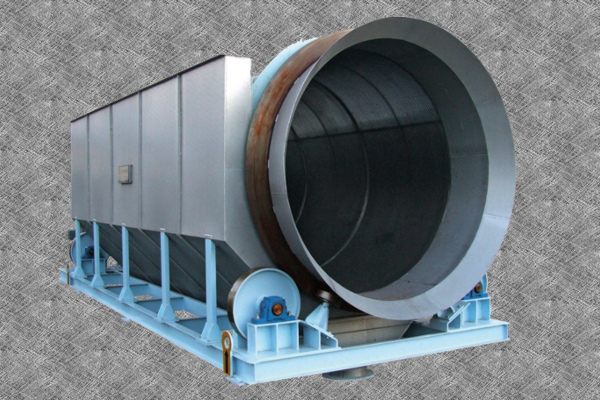

Rotary Filters

Sugar/Alcohol Application

- For applications in sugar processes that require further separation of solids/liquids.

- More than 95% of suspended solid separation with a 0.15 mm mesh.

- Highly efficient in filtering bagasse from mixed and clarified juice from the mill, or the diffuser in the sugar industry.

- Inversion losses are low compared to static cush-cush or DSM alternatives.

- This filter can manage cane juice in extreme conditions – up to 900 t/h.

- Prevents dissolution of lignocellulose compounds, which occur when clarified juice is heated with an alkaline pH.

- Decreased mud production.

- Simple design and effortless cleaning. Guarantees cleaner and decontaminated juice.

- Protects the filtered product and offers greater efficiency in each specific application.

- Absence of hard-to-reach corners makes cleaning a more efficient process while using hot water/steam.

- Increased separation of bagasse is additional biomass for energy production.

- Less solids are sent to mud generating reduction of sugar losses.

- Custom made.

Fly Ash application

- Specially developed for filtering ash water from boiler gas scrubbers.

- Suspended solid separation from liquid effluents in water treatment plants or distilleries.

- Custom made.