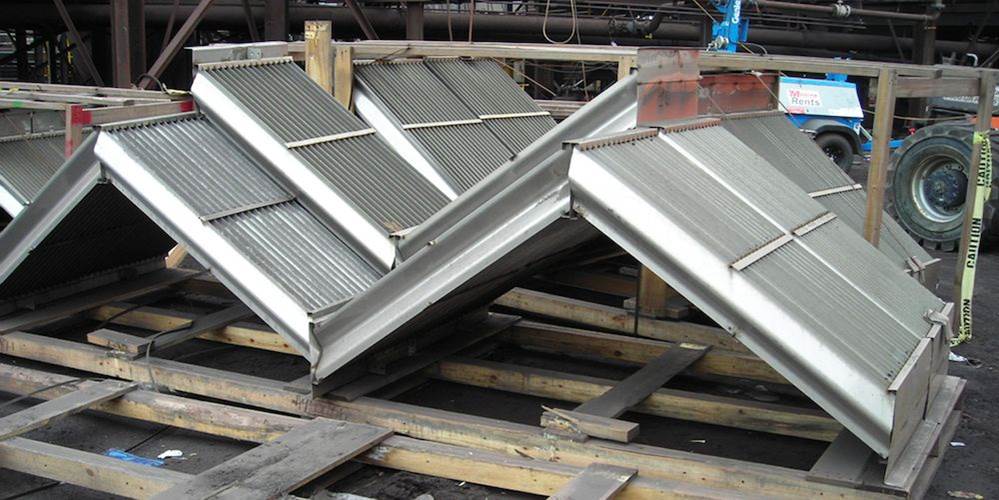

Mist Eliminators

Mist Eliminators for Sucrose Recovery

Sugar Crystallization is the elimination of water by evaporation in sugar cane juice. As the juice evaporation occurs, drops of liquid containing sucrose form on the surface of the boiling sugar solutions and are dragged upward vertically by the ascending steam mass.

The steam speed and the amount of dragged sucrose are proportional due to the disturbances in the operating conditions. These turbulences produce frequent splashes towards the steam’s exit. Different devices have been designed to recover, collect and return strained droplets to the boiling liquid. When the splashes containing sucrose drops reach the vane type carryover separator, 99% of the dragged sucrose is separated. Separators’ locations, inside or outside of working vessel, are analyzed with respect to the operational phase and conditions of the process. Collection and return of separated liquids can be either returned to the main vessel where evaporation and cooking will still be happening, or it could be sent to an external tank.

Maintenance and cleaning have a vital role. Unwanted deposits of solid particles on the vanes will reduce efficiency. The investment on this equipment will be recovered in less than one harvest due to the state-of-art geometry of the vanes, as it outperforms other retaining

designs and leads to enhanced overall efficiency and productivity.