Gears

In Prodek we offer gears and gearboxes designed to fit the needs of every client depending on the application. The design and manufacturing process, as well as the material selection, are of great importance:

- The load capacity of gears is determined by the bending and contact stress, as well as some other factors.

- The stresses are countered by hardness and/or case depth and/or residual stress

- As the loads increase, generally, the tooth size and component size increases.

- As the tooth size and component size increases, casting, forging and heat treatment becomes more complicated.

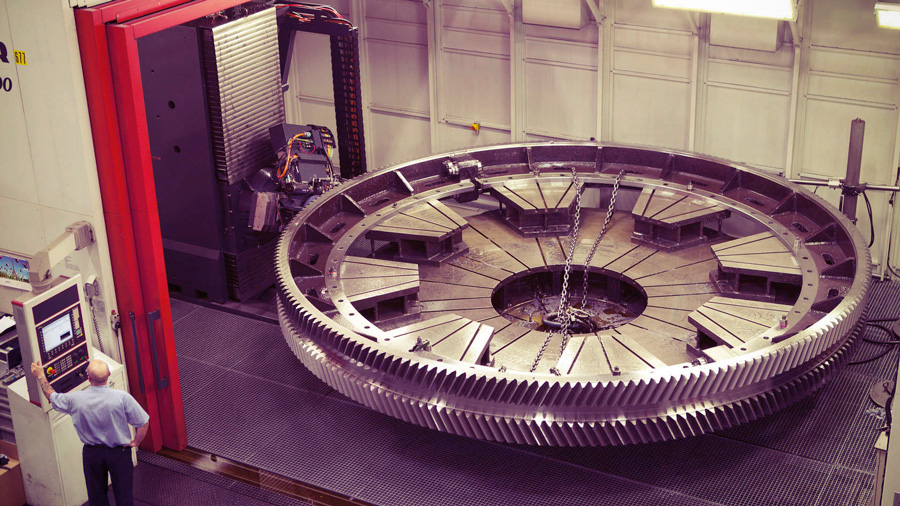

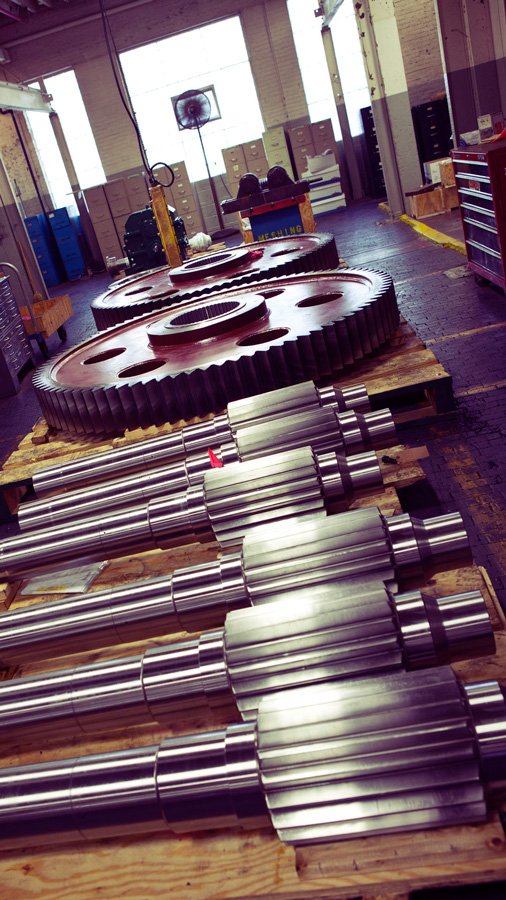

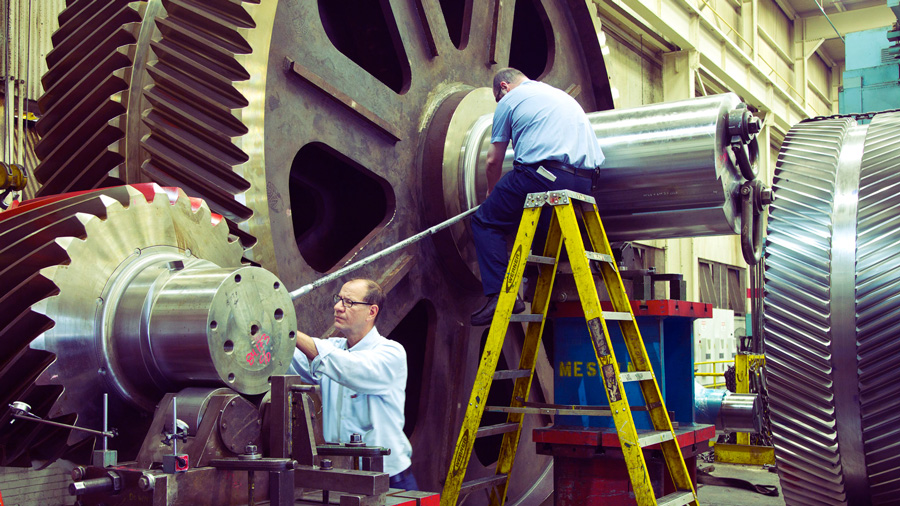

Open gearing and pinions:

- Spur, helical, and double helical, herringbone.

- Shelled pinions, integral pinions, ring gears, planetary gears, fabricated gears, shafts, etc.

- Up to 24 ft. diameter.

- Heat treatment: induction hardening, carburize & harden.

Manufacturing Capabilities:

- Gear cutting, including hobbing, shaping, flycutting, Sykes herringbone, Maag shaping (conventional and hardcutting); up to 288”

- Form grinders to 6 meters (237” diameter) AGMA class 14 with internal grinding capability to 137”OD gear blank.

- Vertical turning to 50’ with live spindle. Shaft turning to 76” diameter. OD grinding to 72” diameter. Keyseating to 60” stroke with indexable table.

- Large welded gear blanks to 238” diameter with furnace stress relieving.

- Horizontal Boring Mills to 9” spindles, 7 axis CNC floor mill with 20’ index table.